1954 - The new "Ikarus 55″ and "66″ buses

Written by the Chief Designer, Béla Zerkovitz

The following study is based on the legendary Ikarus 55-and 66-about type 1954-was published in "Hungarian Technika" and its real value lies in the fact that it is written by none other than Béla Zerkovitz (1912-1993), the chief designer of the bus (who, as his name suggests, was the son of the legendary operetta composer, id. Béla Zerkovitz, but chose a career in engineering rather than the piano.)

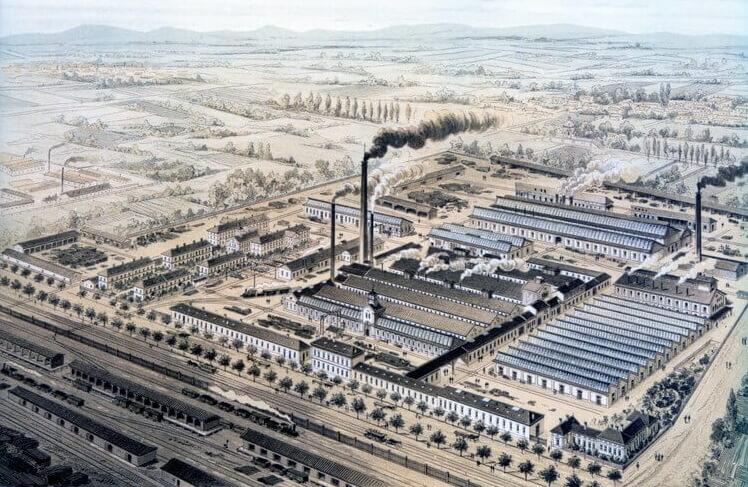

Ikarus 66 - Image source: Transport Museum

As usual, at the end of the post, you will find high-resolution page shots of the article in the gallery.

♠

The growing importance of bus and coach transport requires our domestic industry to produce state-of-the-art models for domestic and largely export use. The directions of development have been reported in several issues of Magyar Technika. This time we present the latest models of our bus and coach industry.

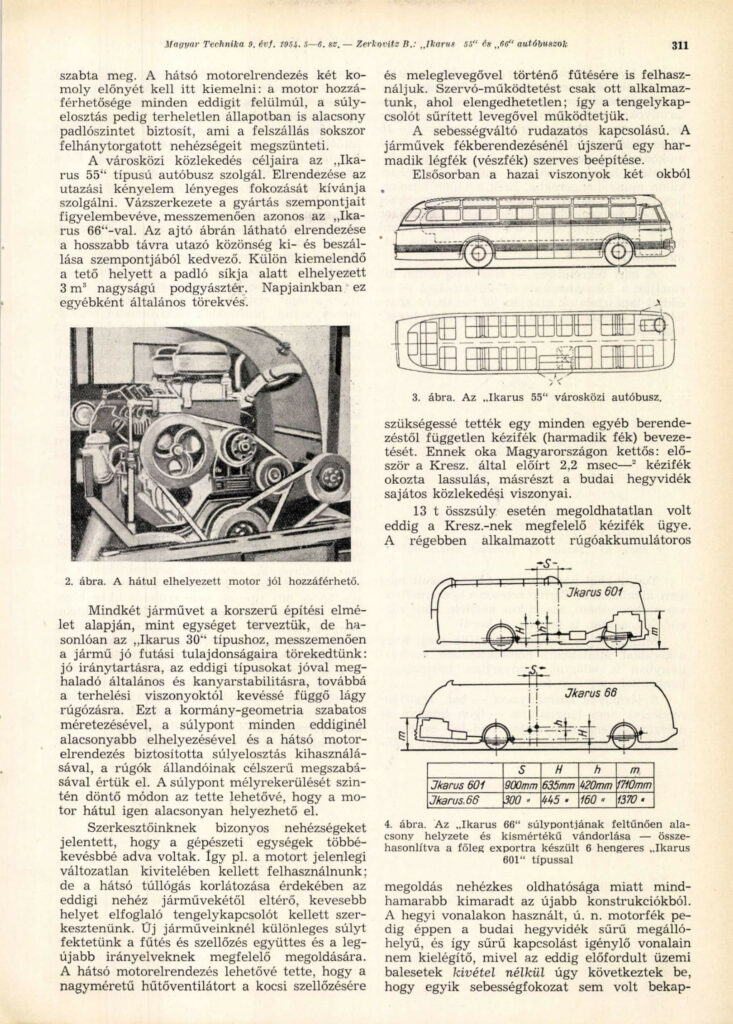

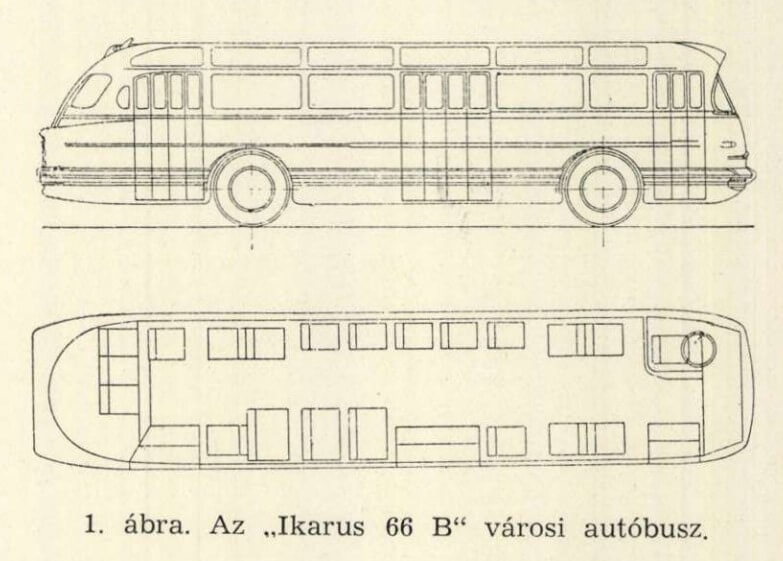

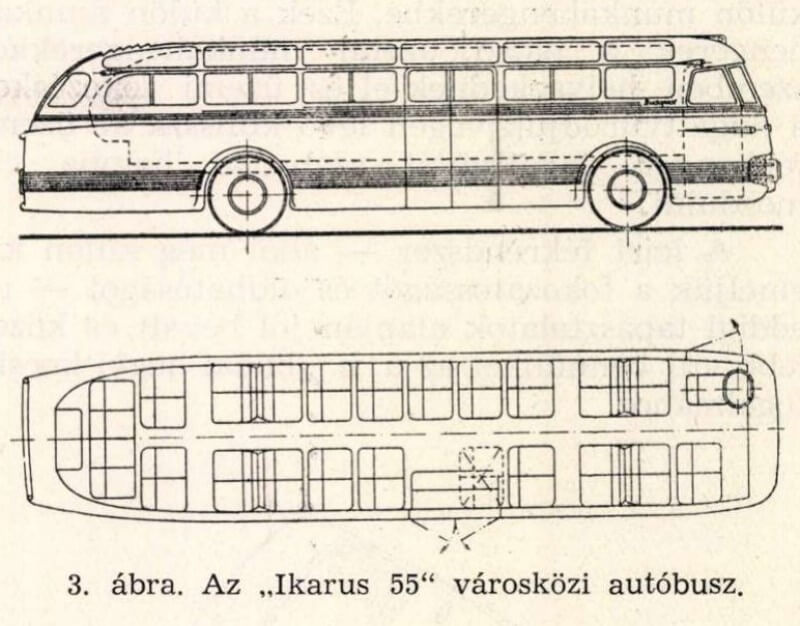

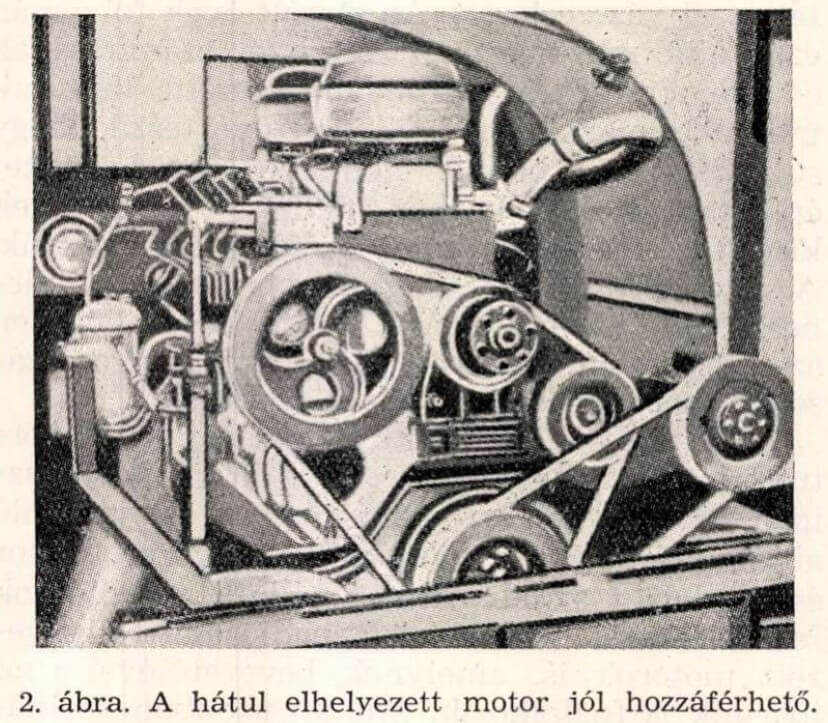

The design of the new types is guided by the decisive aspect of building the most modern large buses available in the country, using the available engineering units. Two types have been designed, the "Ikarus 66" and the "Ikarus 55″, to cater for the different nature of urban and interurban transport. These are also being built as chassis-less self-supporting vehicles, as we have had very good experience with the previous models, which were produced in the thousands. A new feature is that the engine is located at the rear of the coach. The justification and appropriateness of this positioning of the engine is still disputed in the trade press.

Image source: wiki / High Contrast

However, with more trials already underway, the answer to the concerns raised can now be provided directly to practitioners. The design of the city bus was primarily influenced by the traffic conditions in the capital. It has been proven that the traffic demands of Budapest require a vehicle that can carry at least 100 seated and standing passengers in tolerable conditions. The main dimensions of the Ikarus 66 were determined on this basis.

The 22″ wheels eliminate the possibility of overloading. The car's three doors provide good passenger flow. The car's dimensions were limited by two other factors. One is the radius of the turning circle, which must not exceed 10 m to reliably negotiate the tightest bends in the capital. On the other hand, the car's dimensions were limited by the power of the available Csepel 613D tip. 6-cylinder, 125 hp engine. Two major advantages of the rear engine layout should be highlighted here: engine accessibility is second to none, and the weight distribution ensures a low floor level even when unladen, eliminating the often-maligned difficulty of take-off.

The "Ikarus 55″ bus is used for intercity transport. Its layout is designed to substantially improve travel comfort. Its chassis structure is largely identical to that of the "Ikarus 66″, taking into account the manufacturing aspects. The door arrangement shown in the diagram is favourable for the exit and entry of the public travelling long distances. A special feature is the 3m³ pod compartment below the floor level instead of the roof. This is a common aspiration nowadays.

Ikarus-55 (1959) Image source: Fortepan 129208 / Heinzely Béla

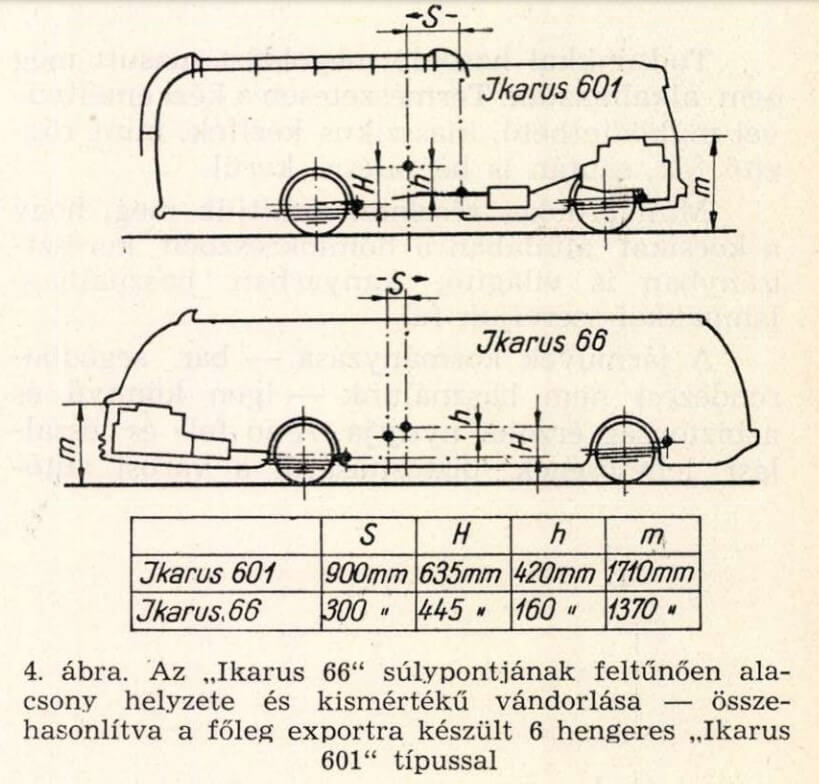

Both vehicles were designed as a unit based on modern construction theory, but like the "Ikarus 30″, the main focus was on good running characteristics: good directional stability, overall and cornering stability well above previous types, and a soft kick that is not too dependent on load conditions. This has been achieved by tailoring the steering geometry, lowering the centre of gravity and taking advantage of the weight distribution provided by the rear engine layout, and by setting the spring constants to a reasonable value. The low centre of gravity was also made possible, crucially, by the fact that the engine can be positioned very low at the rear.

Our editors had some difficulty in that the engineering units were more or less a given. For example, we had to use the engine in its present unchanged design; but to limit the rear overhang, we had to construct a clutch that took up less space than the previous heavy vehicles. For our new vehicles, we put special emphasis on the combined solution of heating and ventilation in accordance with the latest guidelines. The rear engine layout allowed us to use the large cooling fan for both ventilation and heating of the car with hot air. Servo-assisted operation is used only where it is essential, so the clutch is operated by compressed air.

The gearbox is rod-operated. The integral integration of a third air brake (emergency brake) is a novelty in the vehicle braking system.

Firstly, the domestic conditions made it necessary to introduce a handbrake (third brake) independent of all other equipment for two reasons. The reasons for this in Hungary are twofold: firstly, the deceleration caused by the 2.2 msec-² handbrake required by the Kresz.

Ikarus-66 Image source: wiki / Joxy

With a total weight of 13 t, the issue of a handbrake that complies with the Cresz. The earlier kick accumulator solution was soon abandoned in more recent designs because of its cumbersome release. The so-called engine brake used on mountain lines is unsatisfactory, particularly on the lines in the Buda hills, where there are many stops and therefore a high number of gears to be switched, since all the accidents that have occurred so far have been without any gear being engaged. In such cases, the engine brake is ineffective. In the new braking system, the brake compressor also fills a separate reservoir in addition to the normal service reservoirs via a non-return valve. After refilling, this tank retains its contents, which are sufficient for 12-15 full braking operations. A manually operated control valve allows the air to be fed to separate working cylinders capable of actuating the rear brake shoes. These separate working cylinders are positioned opposite the rear service cylinders and, during service braking, the key at the end of their piston rod leaves the service brake cylinder piston free to move.

Ikarus 55 Image source: wiki / Joxy

The described braking system - where we would like to emphasize the gradualness and the release - has worked well based on our experience so far and has brought us closer to the concept of the so-called "Buda mountain car".

To our knowledge, a similar solution has not been applied elsewhere. Naturally, the classic handbrake, which can be operated with a hand lever, will also be installed as a parking brake.

An interesting detail is that the wagons are usually equipped with transverse lights in the front part of the wagon, which can be used in bends.

Steering the vehicles - although no assisted steering is used - is very easy and gives a feeling of safety. Good boarding and alighting facilities have already been discussed in the city car-bus section. A special mention should be made of the opening double doors on the touring coach, together with the opening of a ramp that descends to a sufficient height.

We have retained the curved roof windows on our vehicles, as they help to illuminate the passenger compartment and provide a better view for standing passengers. This solution is now common worldwide.

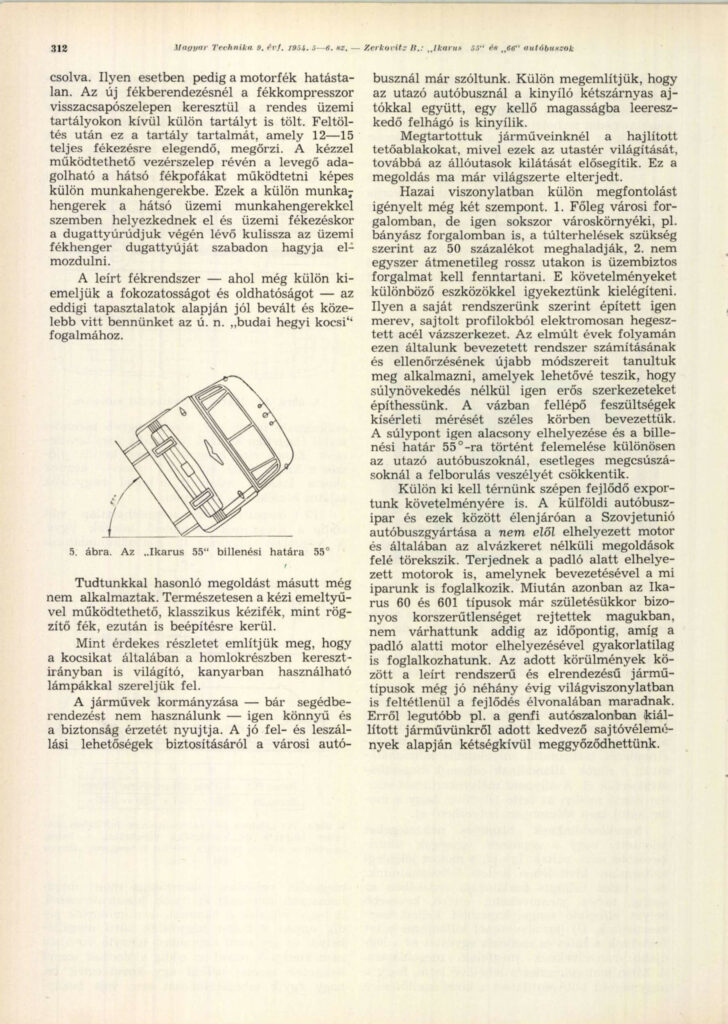

1962 Austria, Vienna, Maria-Theresien-Platz, bus parking lot. Image source: 201735 / Antal Jakab

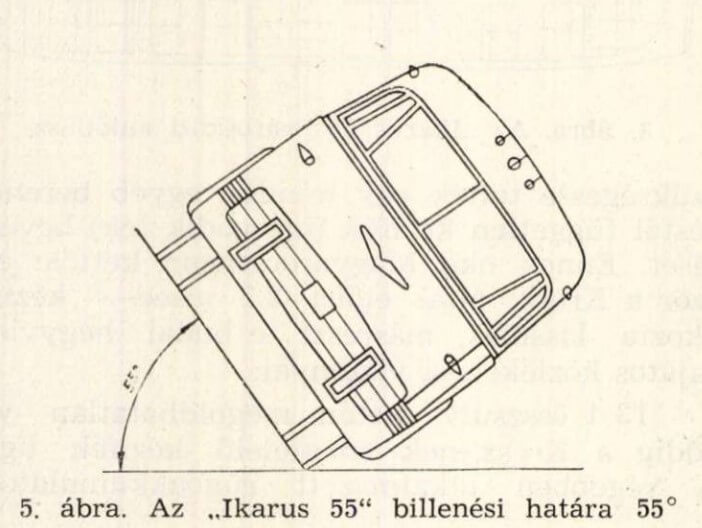

In the domestic context, two other aspects required special consideration. 1. in urban traffic in particular, but very often also in peri-urban traffic, e.g. mining traffic, congestion may exceed 50 percent, 2. traffic must be kept safe even on temporarily bad roads. We have tried to meet these requirements by various means. One of these is the electrically welded steel frame structure, built according to our own system from very rigid extruded sections. In recent years, we have learned new methods of calculating and checking this system, which we have introduced, enabling us to build very strong structures without increasing the weight. Experimental measurements of the stresses in the frame have been widely introduced. The very low positioning of the centre of gravity and the raising of the tipping limit to 55º reduce the risk of overturning, particularly in the case of buses in motion, in the event of possible slips.

We must also make a special mention of the requirement for our exports, which are developing nicely. The foreign bus industry, and among them the Soviet Union, is at the forefront of the trend towards non-front-mounted engines and chassis-frame-less solutions in general. Underfloor engines are also spreading, and our industry is working on introducing them. However, as the Ikarus 60 and 601 models were already somewhat outdated at the time of their birth, we could not wait until we could practically deal with the underfloor engine. Under the circumstances, the vehicle types with the system and layout described will definitely remain at the forefront of development worldwide for some years to come. The favourable press coverage of our vehicle at the Geneva Motor Show, for example, has undoubtedly convinced us of this.

♠